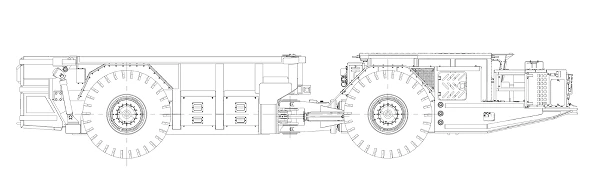

HT24E gains momentum

The end of the year does not mean a slowdown at KGHM ZANAM. In recent weeks, one of the key stages of the battery assembly has been completed in the assembly hall. This has allowed the first tests of the electrical system and calibration of the HT24E’s drive system to begin.

A haulage vehicle with a net weight of 31 tonnes and a load capacity of 24 tonnes, the HT24E features a modular battery system with a capacity of 439 kWh, designed for high operational efficiency and reliability in mining conditions. The scalable battery design allows the energy capacity to be precisely matched to the height limitations of the excavation, optimising the machine’s configuration for specific operational and cost requirements. The HT24E is designed to operate in low underground workings and in the harsh environmental conditions of KGHM, including high humidity and temperatures. The electric drive used is characterised by low heat emissions, which is crucial for underground work.

The drive system is based on four independent and individually controlled electric motors built into the wheel hubs, with an energy recovery function. Another vital element of the design is the separation of the cooling systems – one for the battery and one for the drive – which significantly increases the machine’s safety and reliability.

In 2026, the HT24E is scheduled for underground trials, where its solutions will be tested in real operating conditions.

The new vehicle is part of KGHM ZANAM‘s consistent electromobility development efforts. The company has been using battery power in SWS blaster machines for years and also operates ZANPER battery-powered vehicles. More of these machines will soon be leaving the assembly hall.

The HT24E is a strong finish to the year and a clear signal that KGHM ZANAM is consistently developing state-of-the-art electric solutions for underground mining.