Foundryman’s Day – A Form That Endures

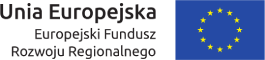

The KGHM ZANAM Foundry – Where Metal Takes Shape

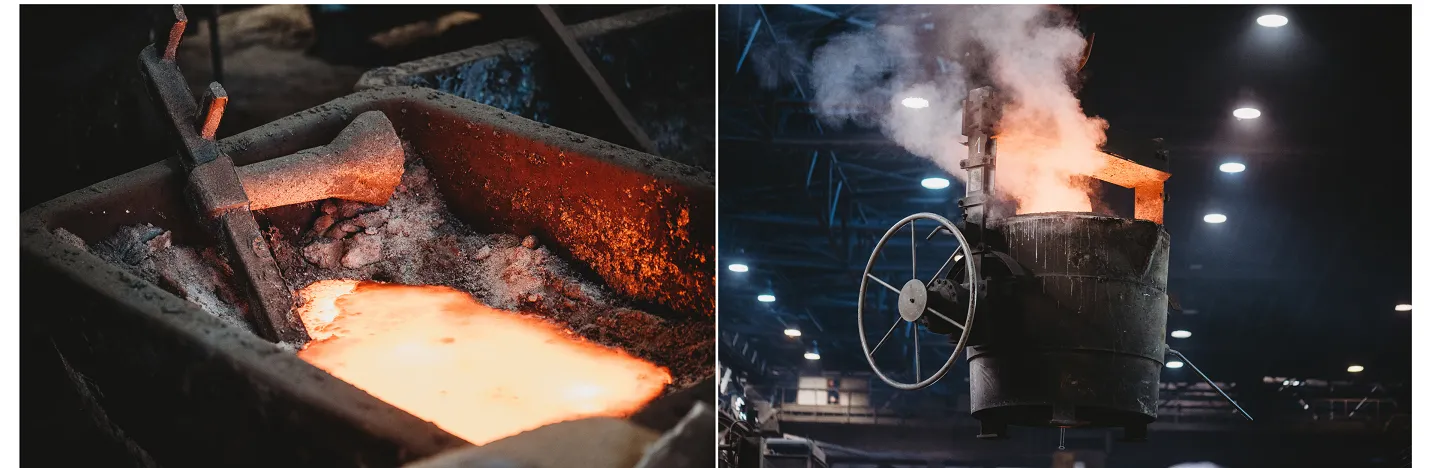

At KGHM ZANAM, the foundry represents more than just technology and hard work. It is a department that has supported production and supplied spare parts for machines and equipment for decades. We manufacture cast steel and cast iron components across a wide weight range, and our production flexibility allows us to execute both short runs and individual, specialised orders.

The quality of our castings is underpinned by a modern technological process. We utilise FLOSTER self-hardening sand technology and electric arc furnaces, while heat treatment is conducted in fully automated annealing furnaces. Consequently, every casting possesses the appropriate structure and properties required to operate in the demanding conditions of the mining, metallurgical, and energy sectors.

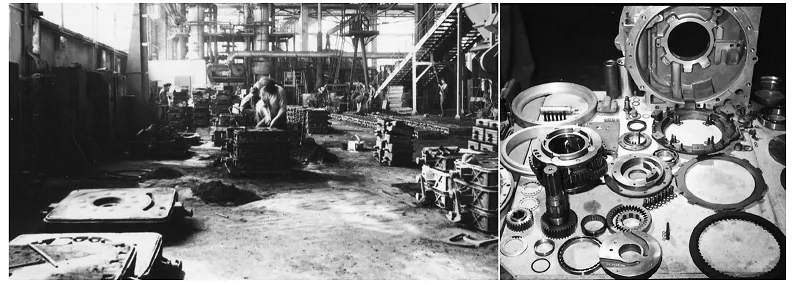

Roots Reaching Back to 1969

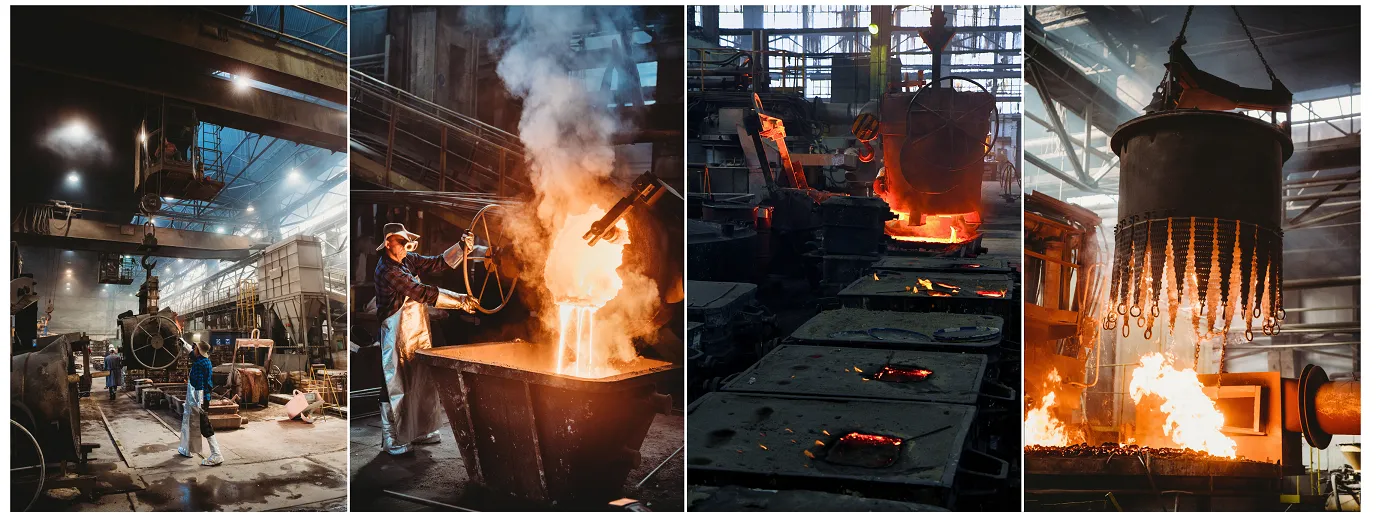

The foundry was established to ensure that Legmet, the predecessor of today’s KGHM ZANAM, had constant access to spare parts. It was the only cast steel foundry in Lower Silesia, with the first melts beginning as early as September 1969. The crew mastered this new craft in no time. In the years that followed, the foundry expanded its competencies and product range: from grey and spheroidal cast iron to carbon cast steels and wear-resistant high-manganese steel.

Although working realities were vastly different back then – involving hand rammers, immense dust, high temperatures, and heavy moulds – the foundry went from strength to strength. In the 1970s, the production of brake housings for mining machines alone reached 30,000 units annually. At that time, the foundry employed over 500 people.

Difficult Work, But With Character

The foundry has always been a special place. Everyone who started here quickly learned that this craft teaches precision, patience, and cooperation. Many of our employees recall those years with a mixture of sentiment and pride. Although the conditions were demanding, the atmosphere was unique; people knew one another, spent time together after work, and the team formed a close-knit community.

Modernity and Experience in One Place

Today, the KGHM ZANAM foundry looks completely different from how it did in the 1970s. A new dust extraction system is in operation, the hall has been insulated and renovated, and processes have been automated. Instead of manual moulding, we now work with self-hardening sands. Employees use modern visors, anti-vibration gloves, and full protective equipment.

Despite many changes, one thing remains certain: the expertise and experience of our crew. It is thanks to our employees that we can continuously develop our technology and increase the foundry’s production capabilities.

Our castings are used in key industrial processes and are delivered to plants across Poland, where they operate at full capacity for years.

People Are at the Heart of This Story

A contemporary foundry relies on technology, but above all, it relies on people. It is they who ensure the quality of the metal, the safety of the process, and that every order meets the high requirements of our clients.

On their special day, it is worth remembering that behind every casting stands a specific person, along with their knowledge, precision, and experience. It is thanks to the foundrymen that KGHM ZANAM has been able to build its longstanding position as a supplier of reliable parts and products for the industry.