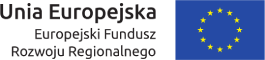

Wear-resistant castings

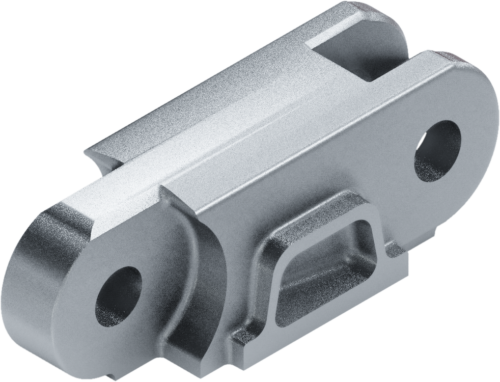

KGHM ZANAM manufactures high-quality wear-resistant castings for working parts of wheeled and tracked machines, excavators, and loaders.

We supply high-quality wear-resistant castings for working parts of wheeled and tracked machines, excavators, and loaders.

High wear resistance is achieved by manufacturing castings from selected grades of cast steel and applying appropriate heat treatment. Cast steel selected in this way can be used to make castings such as bucket teeth, bucket corners, track chain links, blade covers, scrapers, etc.

The structure of wear-resistant castings contains chromium, molybdenum and vanadium carbides. Wear-resistant materials can work longer than other materials, which translates into fewer replacements and repairs, thus reducing downtime and increasing machine efficiency.

Cast iron castings are also characterised by high hardness, due to the formation of a suitable matrix structure during the metastable solidification of cast iron. White cast iron is an example of this.

Carefully selected chemical composition and heat treatment of the alloys guarantee the high quality and reliability of the wear parts. The castings are checked for the required hardness and microstructure to confirm that they have been heat treated correctly.

If you need help selecting the right spare parts for the working systems of wheeled and tracked machines or want to improve the performance of your equipment, please contact us.